Water treatment plants are often operated and maintained 365 days a year. Variations in flows, maintenance, and work load occur, making it imperative that maintenance be planned and scheduled so that there is no idle time or peak workload periods. Maintenance planning and scheduling involves time, personnel, equipment, schedules, costs, work orders, and priorities. The personnel should continuously monitor the operations to determine other maintenance work to be accomplished. When emergencies and breakdowns occur, these tasks must be reviewed and work initiated to return the system to its full capacity and efficiency.

Work Order System

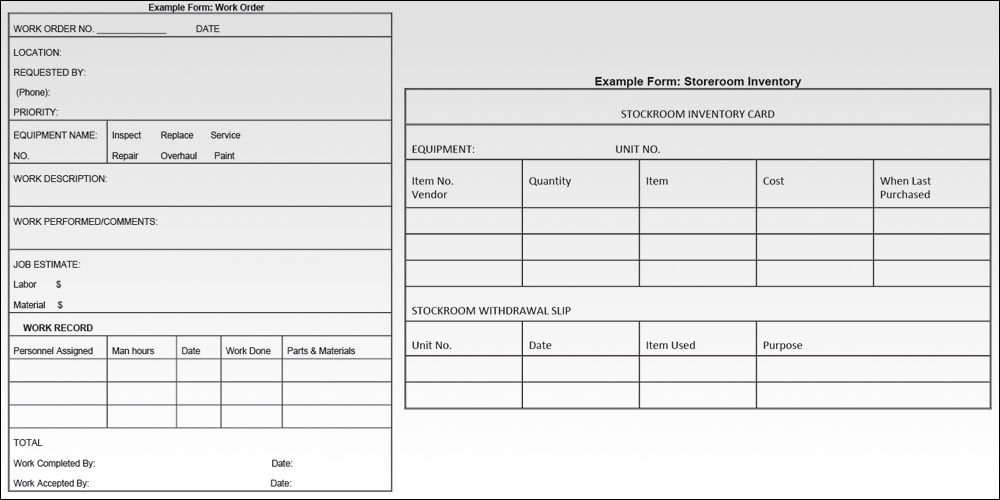

A Work Order System should be established in order to track all non-routine (corrective) maintenance tasks. The use of this system will aid the personnel in identifying the repair work to be accomplished, the priority of the job, and any special information (such as tools or parts needed) or aspects of the equipment or job. Also, a record of these work orders will provide information as to when the work order was initiated and when the job was completed. The work orders should be numbered to provide a means of maintaining accountability. Records of these work orders may give valuable information in regard to estimating future non-routine (corrective) maintenance for planning purposes. During regular inspections, the need for non-routine maintenance on various structures or pieces of equipment may become evident. If the personnel have time, the work should be done as the need arises; therefore, no backlog of pending work will develop. If inspections show more work than can be done immediately, then a backlog of work will develop. The personnel can then use this backlog (or list of jobs to do) to effectively plan the maintenance schedule to smooth out the work load. When a backlog develops, the most critical unit should be repaired first, if parts and materials are available. Any parts ordered should be placed immediately. When the parts arrive, the job should then be scheduled in regard to the unit’s importance in system operation.

Example Form: Work Order (PDF)

Example Form: Work Order (Microsoft Word)

Storeroom and Inventory System

A well-stocked spare parts room and inventory should be developed and maintained. The exact amount and type of parts which are kept in this inventory can only be determined by the personnel’s experience with the system. The proper inventory should be developed by periodic review of the maintenance records. Appropriate changes may be made by increasing stocks of some equipment or decreasing others as determined by experience. The critical nature of parts should be considered in developing the inventory. Spare parts for the blowers, pumping equipment and engine-generators should be considered critical items and should be on hand at all times so that the repairs to these units can be started as soon as they are required.

A card or computer system should be set up to record information on quantity, item number, description, when last purchased, cost, date, vendor, etc. When items are taken from stock, the date and use should be noted in the file. A store ticket or withdrawal slip should also be completed when items are used. The ticket is a record showing when the item was used and for what purpose. This information can aid in determining what is needed when reordering is required. This system will provide an inventory of items currently in stock. Below is an example of the information which should be recorded on the card or computer system monitoring the storeroom.