CAC System Manufacturer O&M (PDF)

Description

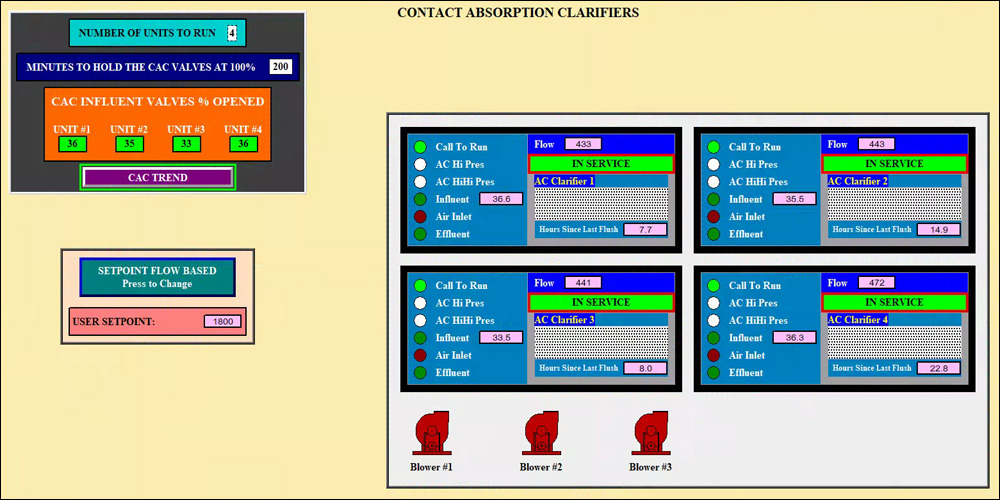

RW supply enters the plant through piping including a flow meter, chemical injection ports for Alum and Polymers, and a static mixer. The total RW (Influent) flow is split evenly through the CAC units by actuated butterfly valves and flowmeters on the inlet piping of each unit. Four (4) CAC units are available for treatment and are on-line or off-line based on the inlet butterfly valve position and flow meter provided information which is processed by the equipment control panel CP-200. RW flows into the bottom of the CAC tank with up flow through the bead media and retainer screen into a trough. The trough conveys water to a box where pipes for TW and BWW are connected. Whether the valve on the TW pipe is open or not is determined by whether the CAC is in service or in flush mode (backwash).

A pressure switch mounted to the side of the CAC tank is set to monitor head loss below the bead media and automatically initiate a flush or notify operators of the need to flush when the head loss exceeds a manufacturer determined set point. A second pressure switch with a higher setpoint will shut down the CAC unit completely to protect the CAC components from damage. Timers can also be programmed to automatically initiate flushes using operator adjustable input. Manual initiation of a flush is available by a start push button. When a flush begins, the TW valve closes backing up water in the effluent box, which is discharged through the BWW pipe. The ALP valve opens and the blower starts to provide air into the CAC tank which causes the bead media to agitate, sink, and expand. Solids are scoured from the media and discharged over the top of the CAC outlet trough. After the flushing period, the RW valve closes and the blower runs to level the media. A short off-line timer is used for a period of no air or water as the media floats up to the retainer screen. Following that, the RW valve is reopened with the TW effluent valve closed, which initiates a clarify-to-waste sequence. When the clarify-to-waste time period is complete, the RW valve is closed, the trough drains, and then the TW and RW valves are opened to put the CAC unit back into service. Clarify-to-waste time is operator adjustable based on observations of performance balancing the desired CAC effluent quality with limiting the amount of flush water wasted.