Gas Chlorine System Manufacturer O&M (PDF)

Gas Chlorine System

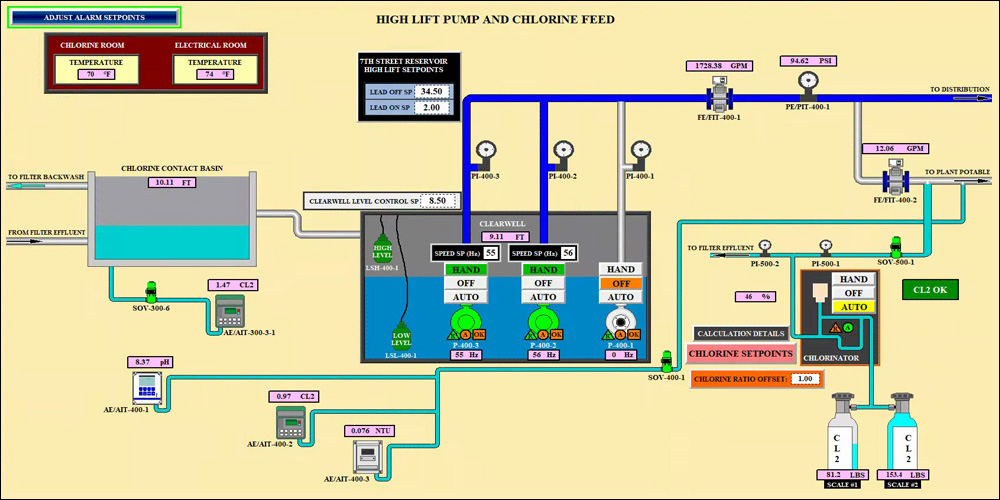

Gas chlorine is injected into filtered water prior to entering the contact basins. The intention of chlorine addition is to provide disinfection of the water with respect to log removal/ inactivation for Giardia and viruses. There are two chlorine application scenarios for the plant. The first is direct filtration which will occur if the contact adsorption clarifier (CAC) process is not on-line and the second is the normal operation with both CAC and filtration steps. Feed requirements for gas chlorine are expected to range from 20-75 lb/day.

The Surface Water Treatment Rule (SWTR) requires 3-log removal (filtration) and/or inactivation (disinfection) of Giardia and 4-log removal and/or inactivation of viruses for the WTP. Since the WTP uses conventional filtration, the SWTR allows 2.5-log Giardia removal credit plus 2.0-log virus removal credit. Chlorination provides the additional 2-log virus inactivation and 0.5-log Giardia inactivation.

Montana DEQ calculates the required and achieved CT valves based on the daily peak water production rate, the measured low water level in the chlorine contact basin (actual volume) combined with an applicable baffle factor, measured low chlorine residual, water temperature, and pH. Residual chlorine levels at the WTP are typically near 1.0 mg/L at peak flow rates based on Montana DEQ compliance form records. Typical winter water temperatures are approximately 5-deg C with a pH of 8.0. Based on these conditions, the required CT for 0.5-log Giardia inactivation is then 40 mg/L-min and the required CT for 2-log virus inactivation is 4 mg/L-min. Therefore, inactivation of Giardia is the controlling factor.

Five separate basins are used to provide the required contact time and finished water storage for the Glasgow WTP. The chlorine contact basins include the repurposed recarbonation basin, contact basin 1, contact basin 2, and the old filter effluent box. The clearwell provides finished water storage and also contributes to chlorine contact time. The DEQ approved baffle factors, gross volumes, and effective volumes are presented in Table 3-1. The volumes shown in Table 3-1 are based on the minimum water level for each basin.

As an example, Giardia CT calculation, given the total effective volume of the four chlorine contact basins of 120,906 gallons and a production rate of 2,100 gpm (conservative for wintertime production), the effective contact time is 57 minutes. The calculated CT value is 57 mg/L-min using a chlorine residual of 1.0 mg/L, and the inactivation ratio under these conditions is 1.4, exceeding the 1.0 minimum requirement. Considering the clearwell contribution to contact time, given the total effective volume of all five basins of 126,083 gallons and the conservative flow rate of 2,100 gpm, the contact time is 60 minutes. Given a chlorine residual of 1.0 mg/L, the calculated CT with the clearwell is 60 mg/L-min and the inactivation ratio is 1.5.

Chlorine Contact Basin Volume

| Basin | Gross Volume (gal) | Baffle Factor | Effective Volume (gal) |

| Repurposed Recarbonation Basin | 7,891 | 0.3 | 2,367 |

| Chlorine Contact Basin #1 (Old Filters) | 56,535 | 0.5 | 28,268 |

| Filter Effluent Box | 2,020 | 0.1 | 202 |

| Chlorine Contact Basin #2 | 180,137 | 0.5 | 90,069 |

| Clearwell | 51,776 | 0.1 | 5,178 |

| Total Effective Volume = | 126,083 |